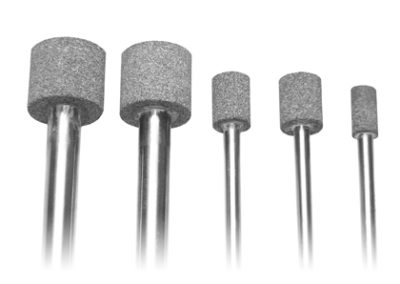

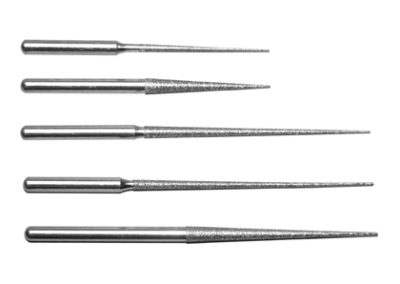

Electroplated Diamond / CBN Wheel

| Electroplated Diamond / CBN Wheel

Electroplated wheels are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity.

Besides, these tools are noted for:

- Allow special shapes and profile tools to be made at short notice.

- Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Wheel

- Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325.

- Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. We could also combine different grit sizes in the same diamond mounted point.

- Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel.

- Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or rimming aluminum oxide wheel.

| PCD & PCBN Turning Tools

PCD & PCBN have higher hardness & abrasion resistance than other cutting tools . The advantages of these features are:improving tool’s life, providing better control over part size and surface finishes, reducing tool cost per machined part and improving machine productivity.

Applications :

- Polycrystalline Diamond (PCD)

Aluminum alloys、copper alloys、manganese alloys

Sintered carbide & ceramics

Green or semi-sintered carbide & ceramics

High-silicon aluminum alloys

Reinforced plastic、hard rubber、carbon、graphite - Polycrystalline Cubic Boron Nitride (PCBN)

Hardened steels (HRC 45 ~ 68)

Tempering steels

Super alloys: Cobalt and nickel base super alloys

Cast iron: Chilled iron, Meehanite iron

Sintered ferrous alloys: SCM, SNCM

| Diamond Compound (Paste)

Remark

- Oil soluble is standard carries, other carries depend on your request.

- Containers : Plastic syringes, 5 grams per syringe.

- Others (10 or 18 grams) depend on your request.

- We also supply thinners for your special applications.

- High concentrations diamond compounds is also available, depend on your requirement.

|

Order no. |

Micron range |

Mesh size |

Color code |

|

PDR-280 |

0.5 (0-1) |

#28,000 |

White |

|

PDR-140 |

1 (0-2) |

#14,000 |

White |

|

PDR-080 |

3 (2-4) |

#8,000 |

Yellow |

|

PDR-050 |

4.5 (3-6) |

#5,000 |

Light brown |

|

PDR-030 |

6 (4-8) |

#3,000 |

Orange |

|

PDR-020 |

8 (6-10) |

#2,000 |

Lilac |

|

PDR-018 |

9 (6-12) |

#1,800 |

Green |

|

PDR-015 |

13 (10-16) |

#1,500 |

Pink |

|

PDR-012 |

15 (10-20) |

#1,200 |

Blue |

|

PDR-010 |

17.5 (15-20) |

#1,000 |

Dark green |

|

PDR-008 |

25 (20-30) |

#800 |

Brown |

|

PDR-006 |

35 (30-40) |

#600 |

Red |

|

PDR-004 |

50 (40-60) |

#400 |

Purple |

|

PDR-002 |

90 (80-100) |

#200 |

Black |

| Products

Automatic Lubricator

Accessories For Lubrication System

Machine Tools Accessories

VERSADA are investing inappropriate level of stocks to bridge the gap between users and manufacturers, this business model has enabled VERSADA to respond promptly and delivering the necessary products in the needed amounts at the right time with the competitive price.